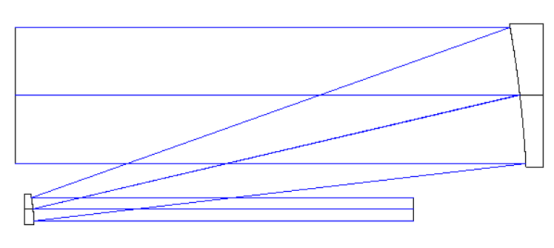

The traditional manual method is adopted to process the lager diameter parabolic and hyperbolic lens with BK7 (ZK N4 or Zerodur) material, use knife-edge instrument for test, with high processing accuracy, and the diameter can be within 900mm.surface accuracy could be less than 1/40 lambda. Through high precision parallel light tube, combined processing method to ensure the image quality of primary and secondary mirror combined system. With knife-edge instrument, the spot size can be controlled within 0.02mm.It can also process non-focal beam expansion system, that is, Parallel light comes in and parallel light comes out.Expansion can be designed according to customer requirements.

Through the way of sleeve, the high precision off-axis mirror combination could be obtained.

| Material | BK7, ZK N4 ,Zerodur ect. |

| Diameter tolerance | +0.0/-0.15mm |

| Diameter of primary and secondary mirror | ≤900mm |

| Structure of Primary and secondary mirror | Parabolic+ Parabolic /Parabolic +Hyperbolic |

| Type | Primary and secondary mirror imaging/Afocal system |

| Focal length tolerance | ±2% |

| Clear aperture | ≥90% |

| Light spot | 0.02mm |

| Surface Quality | 60-40 |

| Bevel | 0.25 mm × 45° |

| Coating | Metal reflection coating/Dielectric reflection coating |