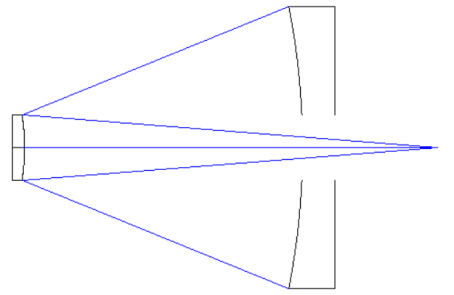

The traditional manual method is adopted to process the lager diameter parabolic and hyperboloid lens with BK7 (ZK N4 or Zerodur) material, use knife-edge instrument for test, with high processing accuracy, and the diameter can be within 900mm.surface accuracy could be less than 1/40 lambda. Through high precision parallel light tube, combined processing method to ensure the image quality of primary and secondary mirror combined system. With knife-edge instrument, the spot size can be controlled within 0.02mm.It can also process non-focal beam expansion system, that is, Parallel light comes in and parallel light comes out.Expansion can be designed according to customer requirements.

| Material | BK7, ZK N4 ,Zerodur ect. |

| Diameter tolerance | +0.0/-0.15mm |

| Diameter of primary and secondary mirror | ≤900mm |

| Structure of Primary and secondary mirror | Paraboloid+ Paraboloid / Paraboloid +Hyperboloid |

| Type | Primary and secondary mirror imaging/Afocal system |

| Focal length tolerance | ±2% |

| Clear aperture | ≥90% |

| Light spot | 0.02mm |

| Surface Quality | 60-40 |

| Bevel | 0.25 mm × 45° |

| Coating | Metal reflection coating/Dielectric reflection coating |