Single point diamond turning

The ultra-precision workshop has a world-leading single-point diamond lathe that can process complex optical surfaces such as aspherical surfaces, hyperboloids, paraboloids, and free-form surfaces on various optical materials. The machining accuracy can reach 1/20λ, and the maximum machinable component can be used. Up to 700mm.

Polish machine

The traditional light processing workshop has dozens of processing equipment and uses classical cold processing technology to process lens optical components of various calibers and various materials.

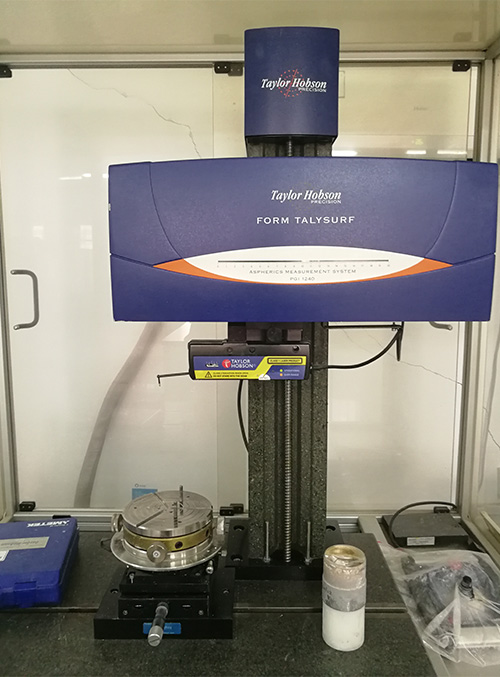

Taylor hobson form talysurf

It is equipped with a Taylor profiler to accurately measure the surface roughness, shape and contour of machined optical components such as polished or single-point diamond cars.

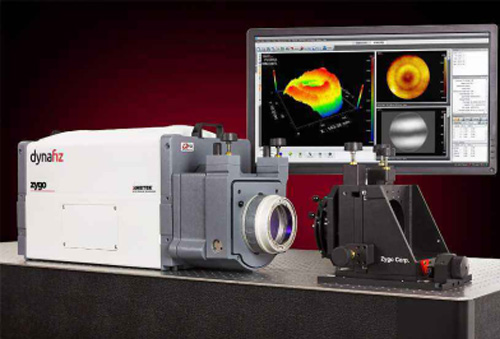

Zygo

Equipped with Zygo interferometer, it can measure the parallelism, surface shape, wavefront and other parameters of the lens and plane system.

Lens assembly

Opticreate equips clean benches, which offer a dust-free condition for precision instruments assemblies.